Milking system

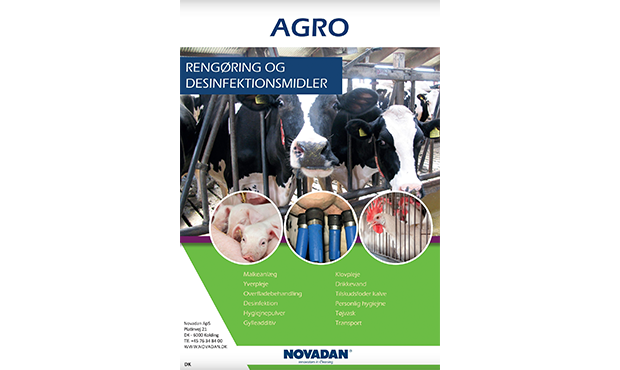

Thorough and effective cleaning of milking equipment is essential to maintaining high milk quality—the primary raw material delivered by the producer for further processing at the dairy. Proper cleaning also plays a crucial role in ensuring that farmers consistently obtain the best possible price for their milk.

To achieve optimal results, it is important to choose the appropriate cleaning products and use them in compliance with applicable regulations. In addition, a number of physical and technical factors—such as the design of the milking system—can significantly influence the overall outcome.

Conventional milking systems typically involve manual or semi-automated processes where milking clusters are attached to cows by hand. The cleaning of these systems involves several key steps:

- Pre-Rinse: Begin with a warm water rinse to remove residual milk from the system.

- Detergent Wash: Use a high-quality alkaline detergent to break down fats and proteins. Ensure the detergent is circulated through the system for the recommended time.

- Acid Rinse: Follow with an acid rinse to remove mineral deposits and prevent scale buildup.

- Sanitization: Before the next milking session, sanitize the system with an approved disinfectant to eliminate any remaining bacteria.

Regular maintenance and inspection of the milking equipment are also vital to ensure all parts are functioning correctly and to prevent contamination.

Milking system

Read more about Novadan products which are developed for cleaning of milking systems. Choose between alkaline, acidic products and disinfectants – products for both carousel and robot systems.

Case story

Search SDS and product sheets

Contact Novadan to hear more about the right solution for your company

Fill in the form with your contact details and area of interest - we will reply as soon as possible.

Platinvej 21 – DK-6000 Kolding

+45 7634 8400

info@novadan.dk